As industries across the world seek to improve production speed, reduce costs, and enhance product quality, automation has become a key driver of progress. Among the many innovations in industrial automation, automated riveting machines stand out for their ability to streamline the riveting process, which is essential in many manufacturing sectors. Expert Technologies Group is a leading provider of automated riveting machines, offering cutting-edge solutions that help manufacturers optimise their production lines and achieve higher efficiency, precision, and consistency.

What is an Automated Riveting Machine?

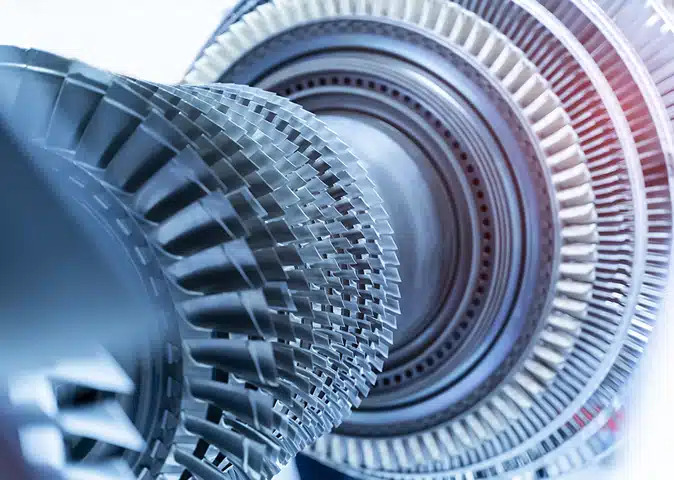

An automated riveting machine is a specialised tool that automates the riveting process—attaching rivets to join materials, typically metals or composites, in a secure and permanent manner. Riveting is a crucial joining technique used in a wide range of industries, from aerospace and automotive to construction and electronics.

In traditional manual riveting, workers insert and secure each rivet by hand, which can be time-consuming and prone to errors. Automated riveting machines replace manual work, providing a much faster and more reliable method for fastening materials. These machines are equipped with advanced sensors and control systems, allowing for high-speed, precise insertion of rivets, ensuring consistent and high-quality results every time.

How Automated Riveting Machines Work

Automated riveting machines are designed to simplify and optimise the entire riveting process. Below are the basic steps involved in their operation:

- Material Alignment: The materials to be riveted are loaded into the machine, where they are automatically aligned to ensure the correct positioning. This ensures that the rivets are placed precisely where needed.

- Rivet Feeding: The machine’s automated system feeds rivets to the correct location, eliminating the need for manual handling. This ensures that each rivet is placed in the correct position and orientation.

- Rivet Insertion and Setting: The riveting head of the machine applies controlled force to the rivet, causing it to expand and securely fasten the materials together. The machine can adjust the force applied depending on the thickness of the materials and the rivet size, ensuring optimal results.

- Quality Control: Many automated riveting machines come equipped with sensors that monitor the process and detect potential defects. These sensors ensure that each rivet is installed correctly and that the finished product meets the required quality standards.

With these automated steps, manufacturers can achieve higher production rates, improve product quality, and minimise errors associated with manual processes.

Key Benefits of Automated Riveting Machines

1. Increased Production Speed

One of the primary benefits of automated riveting machines is the significant increase in production speed. Automated systems can insert rivets much faster than manual methods, allowing manufacturers to meet high production demands and tight deadlines. These machines can operate continuously, further increasing throughput and reducing production lead times.

2. Consistent Quality and Precision

In manual riveting, there is a risk of human error, which can result in misaligned rivets or improperly set joints. Automated riveting machines eliminate this risk, ensuring that each rivet is placed with the same level of precision and force. This consistency is essential, particularly in industries where joint strength and reliability are critical, such as aerospace and automotive.

3. Cost Savings

While the initial investment in an automated riveting machine may seem significant, the long-term cost savings are substantial. These machines reduce the need for manual labour, leading to lower labour costs. Additionally, the increase in productivity and the reduction in defects or errors help companies save on rework, repairs, and product recalls, further improving the return on investment.

4. Improved Worker Safety

Riveting can be physically demanding and involves repetitive tasks that can lead to worker fatigue or injuries. Automated riveting machines take over the physically taxing tasks, reducing the risk of workplace injuries. This improves worker safety and allows employees to focus on higher-value tasks that require their expertise, rather than performing repetitive manual labour.

5. Flexibility

Automated riveting machines are highly versatile, able to handle a range of materials, rivet sizes, and joint configurations. Whether working with thin sheet metal, thicker materials, or complex components, automated riveting machines can be adjusted to meet specific production needs. This flexibility makes them suitable for a wide variety of industries and applications.

Industries Benefiting from Automated Riveting Machines

Automated riveting machines are essential across a broad spectrum of industries. Below are some of the sectors where this technology is having a significant impact:

1. Aerospace

In the aerospace industry, the strength and integrity of every component are critical. Automated riveting machines are used extensively in the assembly of aircraft components, including fuselages, wings, and landing gear. These machines ensure that rivets are placed accurately, helping to meet the strict safety and quality standards required in aerospace manufacturing.

2. Automotive

Automotive manufacturers rely on automated riveting machines for tasks such as assembling car bodies, frames, and other structural components. These machines help manufacturers meet high production volumes while maintaining the quality and safety standards essential in automotive manufacturing. By speeding up the riveting process, automotive companies can boost production efficiency and meet growing demand.

3. Electronics

In the electronics industry, automated riveting machines are used to assemble components like casings, connectors, and enclosures. The precision offered by automated systems ensures that rivets are securely fastened without damaging delicate electronic components. These machines also help manufacturers achieve faster turnaround times, a critical factor in the fast-paced electronics market.

4. Construction

In construction, automated riveting machines are employed to assemble large metal structures such as bridges, buildings, and industrial equipment. The speed and precision offered by these machines allow construction companies to complete projects more quickly while ensuring the structural integrity and safety of the finished product.

Why Choose Expert Technologies Group?

Expert Technologies Group is a trusted provider of advanced automated riveting solutions, offering machines designed to meet the diverse needs of various industries. The company’s innovative technology helps manufacturers improve production efficiency, reduce errors, and enhance overall product quality.

Here’s why businesses should choose Expert Technologies Group:

- Cutting-Edge Technology: Expert Technologies Group delivers the latest automated riveting technology, ensuring your manufacturing processes remain competitive and efficient.

- Customised Solutions: The company works closely with clients to provide tailored riveting solutions that address their specific manufacturing needs, ensuring optimal performance and results.

- Comprehensive Support: From installation and training to maintenance and upgrades, Expert Technologies Group offers full support to ensure your automated riveting machines continue to operate at peak performance.

Conclusion

Automated riveting machines are revolutionising manufacturing by offering faster production speeds, improved precision, and substantial cost savings. By automating the riveting process, manufacturers can optimise their production lines, reduce errors, and maintain consistent product quality.

Industries such as aerospace, automotive, electronics, and construction are already seeing the benefits of automated riveting machines, and with Expert Technologies Group leading the way in innovation, businesses can continue to stay ahead of the competition. Investing in automated riveting technology is a smart move that can improve efficiency, reduce costs, and increase product quality, helping businesses thrive in today’s fast-paced manufacturing environment.