The smart pigging market represents a critical segment within the pipeline inspection industry, providing advanced inspection and maintenance solutions for oil and gas pipelines. This article offers an in-depth overview of the smart pigging market, covering its history, technology, applications, industry structure, key players, and market dynamics.

Technology

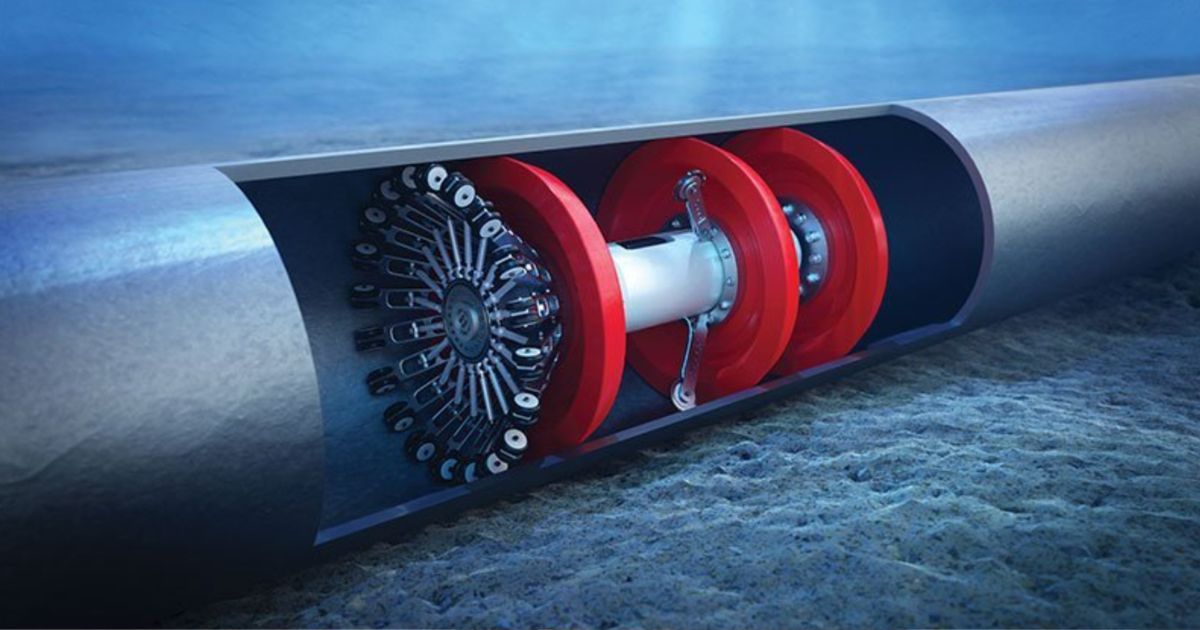

Smart pigs, also known as intelligent pigs or inline inspection (ILI) tools, are sophisticated devices designed to traverse pipelines while collecting data on pipeline geometry, wall thickness, defects, and anomalies. Smart pigs are equipped with advanced sensors, such as magnetic flux leakage (MFL), ultrasonic testing (UT), eddy current testing (ECT), and high-resolution imaging systems, to detect and characterize flaws in pipeline walls.

Key components of smart pigging technology include:

- Sensors: Smart pigs incorporate a range of sensors to measure parameters such as magnetic flux, ultrasonic signals, electrical conductivity, and temperature variations along the pipeline length. These sensors provide detailed information on pipeline condition, including metal loss, cracks, weld defects, and corrosion damage.

- Data Acquisition Systems: Smart pigs are equipped with data acquisition systems to capture, process, and store inspection data collected during the pigging operation. Data acquisition systems may include onboard computers, memory storage devices, and communication interfaces for real-time monitoring and data retrieval.

- Navigation Systems: Smart pigs use navigation systems such as inertial measurement units (IMUs), gyroscopes, and GPS receivers to track their position and orientation within the pipeline. Navigation data enable precise localization of defects, mapping of pipeline features, and correlation with geographic information system (GIS) data for asset management.

- Power and Propulsion: Smart pigs are powered by batteries, onboard generators, or product flow energy to drive propulsion systems such as wheels, brushes, or magnetic crawlers. Propulsion mechanisms enable smart pigs to traverse pipelines of various diameters, grades, and operating conditions, including straight sections, bends, and inclines.

- Communication Interfaces: Smart pigs feature communication interfaces such as radio frequency (RF), acoustic telemetry, or wired connections to transmit inspection data to external monitoring systems or control centers. Communication interfaces enable remote control, real-time data streaming, and post-inspection analysis of pipeline integrity.

Applications

The smart pigging market serves various applications in the oil and gas industry, including:

- Pipeline Integrity Management: Smart pigging is used for routine inspection and integrity assessment of oil and gas pipelines to identify defects, anomalies, and potential integrity threats. Pipeline operators deploy smart pigs to monitor corrosion, cracking, dents, and other forms of damage that could compromise pipeline safety and reliability.

- Corrosion Monitoring: Smart pigs equipped with corrosion detection sensors, such as MFL and UT, are deployed to assess the extent and severity of corrosion in pipeline walls. Corrosion monitoring helps prioritize maintenance activities, implement corrosion control measures, and extend the service life of pipeline assets.

- Crack Detection: Smart pigs employ UT and ECT techniques to detect and characterize cracks, weld defects, and other discontinuities in pipeline welds and joints. Crack detection is essential for identifying structural weaknesses, assessing fatigue damage, and preventing catastrophic failures in high-stress areas of the pipeline.

- Geometry Mapping: Smart pigs utilize laser profiling, MFL mapping, and 3D imaging technologies to map pipeline geometry, including bends, wrinkles, and ovality deviations. Geometry mapping enables operators to assess pipeline integrity, evaluate bending stress, and optimize pigging operations for efficient passage through complex pipeline configurations.

- Pipeline Cleaning: Smart pigs equipped with cleaning tools, such as brushes, scrapers, and pigs with abrasive coatings, are used for pipeline cleaning and debris removal. Pipeline cleaning helps maintain flow efficiency, prevent flow restrictions, and enhance the performance of pigging operations in dirty or fouled pipelines.

Industry Structure

The smart pigging market comprises a diverse ecosystem of companies involved in the design, manufacturing, deployment, and operation of smart pigging technologies. Key stakeholders in the smart pigging industry include:

- Technology Providers: Technology providers specialize in the development and commercialization of smart pigging systems, sensors, data analysis software, and associated equipment. Technology providers invest in research and development to innovate new inspection techniques, improve sensor accuracy, and enhance data interpretation algorithms.

- Service Providers: Service providers offer smart pigging services, including pipeline inspection, data analysis, and integrity management solutions to oil and gas operators. Service providers deploy smart pigs, interpret inspection data, and provide actionable insights to support decision-making in pipeline maintenance and risk mitigation.

- Pipeline Operators: Pipeline operators are responsible for managing and maintaining oil and gas pipelines, including the planning, scheduling, and execution of smart pigging operations. Pipeline operators contract with technology and service providers to conduct routine inspections, integrity assessments, and maintenance activities to ensure regulatory compliance and operational safety.

- Regulatory Authorities: Regulatory authorities oversee pipeline safety regulations, inspection standards, and compliance requirements to protect public safety, environmental quality, and infrastructure integrity. Regulatory authorities set guidelines for smart pigging operations, data reporting, and risk management practices to ensure the safe operation of oil and gas pipelines.

Key Players

The smart pigging market is served by a diverse range of companies specializing in smart pigging technology and services. Some of the key players in the smart pigging market include:

- ROSEN Group: ROSEN Group is a global provider of smart pigging solutions, inspection services, and integrity management software for the oil and gas industry. ROSEN’s smart pigging technologies include ultrasonic, magnetic, and electromagnetic inspection tools for pipeline integrity assessment and defect detection.

- Pigs Unlimited International, Inc.: Pigs Unlimited International, Inc. designs, manufactures, and supplies pigging equipment, including smart pigs, pig launchers, pig receivers, and pipeline cleaning tools. Pigs Unlimited offers custom pigging solutions tailored to specific pipeline applications, sizes, and operating conditions.

- Baker Hughes: Baker Hughes is a leading oilfield services company that provides smart pigging services, pipeline inspection tools, and integrity management solutions for the oil and gas industry. Baker Hughes’ smart pigging technologies include MFL, UT, and EMAT inspection tools for detecting corrosion, cracks, and defects in pipelines.

- NDT Global: NDT Global specializes in ultrasonic inline inspection (UT ILI) technologies for pipeline integrity assessment, crack detection, and geometry measurement. NDT Global offers a range of smart pigging solutions for gas transmission pipelines, liquid pipelines, and pipeline networks worldwide.

- Halliburton: Halliburton is a multinational energy services company that offers smart pigging services, pipeline diagnostics, and integrity solutions for upstream and midstream oil and gas operations. Halliburton’s smart pigging technologies include magnetic flux leakage (MFL) and ultrasonic inspection tools for pipeline condition assessment and anomaly detection.

Market Dynamics

The smart pigging market is influenced by various factors that drive demand for pipeline inspection and maintenance services, including:

- Pipeline Aging: Aging infrastructure, including pipelines installed decades ago, requires regular inspection and maintenance to mitigate corrosion, fatigue, and mechanical damage that could compromise pipeline integrity and reliability.

- Regulatory Compliance: Regulatory mandates, industry standards, and safety regulations require pipeline operators to conduct periodic inspections, integrity assessments, and risk evaluations to ensure compliance with regulatory requirements and maintain operational safety.

- Asset Management: Asset owners and operators prioritize asset integrity management, risk-based inspection (RBI), and predictive maintenance strategies to optimize asset performance, extend service life, and minimize downtime in pipeline operations.

- Safety and Environmental Concerns: Concerns about pipeline safety, environmental protection, and public health drive investments in smart pigging technologies, leak detection systems, and integrity management programs to prevent spills, leaks, and environmental incidents.

- Technological Advancements: Advances in sensor technology, data analytics, and artificial intelligence (AI) enable the development of next-generation smart pigging systems with enhanced inspection capabilities, data accuracy, and predictive analytics for proactive maintenance and asset management.

Future Outlook

The smart pigging market is poised for continued growth and innovation, driven by emerging trends and developments in the oil and gas industry, including:

- Digital Transformation: The adoption of digital technologies, IoT sensors, and cloud-based analytics platforms enables remote monitoring, data visualization, and predictive maintenance in smart pigging operations, improving efficiency, reliability, and decision-making in pipeline management.

- Robotics and Automation: The integration of robotics, drones, and autonomous vehicles in smart pigging operations enhances inspection coverage, accessibility, and safety in challenging environments, such as subsea pipelines, offshore platforms, and remote locations.

- Data Integration and Interoperability: The integration of smart pigging data with other asset information, such as GIS data, SCADA systems, and maintenance records, enables holistic asset management, risk assessment, and decision support for pipeline operators.

- Sustainable Pipeline Management: The adoption of sustainable practices, environmental stewardship, and circular economy principles drives investments in pipeline integrity, leak detection, and emissions reduction technologies to minimize environmental impact and ensure long-term sustainability of pipeline assets.

- Global Expansion: The expansion of smart pigging services in emerging markets, including Asia-Pacific, Latin America, and Africa, presents growth opportunities for technology providers, service contractors, and asset owners seeking to improve pipeline safety and compliance in rapidly developing regions.